LB-Co-extrusion rua paparanga wpc profile extrusion raina

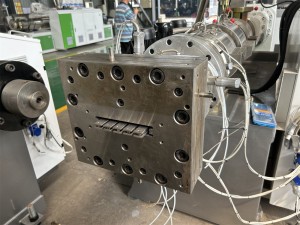

Raw material +mana rakau+ additive → ranu → granulating → conical twin-screw extruder → profile extrusion mold → cool molding die → vacuum calibration support →haul-off → cutter → rack → finished product

1> Koeko Wiu rua extruder: SJSZ-65/132

2> WPC PP/PE/PVC matapihi, tatau, taiapa, rahoraho, reeti, hangai kōtaha papa

3> Pūnaha whakatikatika korehau

4>Hauhia te miihini

5> Miihini tapahi

6> Te awhi tuku

7> Whakaranu

8> Miihini embossing

| Tauira Extruder | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Te mana motuka(kw) | 22 | 37 | 55 | 110 | ||

| Hua whanui | 200 | 240 | 300 | 600 | 900 | 1200 |

| Te mana korehau | 4kwX1 | 5.5kwX1 | 5.5kwX1 | 5.5kwX2 | 5.5kwX1 7.5kwX1 | 5.5kwX1 7.5kwX1 |

| papu wai | 2.2kw | 2.2kw | 4kw | 5kw | 7.5kw | 7.5kw |

| Te tere hopu | 0-5m/min | 0-5m/min | 0-5m/min | 0-3m/min | 0-2.5m/min | 0-2.5m/min |

| Raukaha (kg/h) | 70kg/h | 110kg/h | 110kg/h | 170kg/h | 300kg/h | 300kg/h |

| Taumaha Kupenga(kg) | 3000 | 5000 | 6500 | |||

Mena he PE, he PP ranei nga rauemi mata, me whakakotahi koe i te paura rakau + te matūriki PP/PE, katahi ka maka ki roto ki te raina pelletizing, ka mutu ka whiwhi pire kirihou rakau whakamutunga.